Sustainability in manufacturing processes is increasingly becoming a critical consideration for industries worldwide. According to the International Energy Agency, the demand for batteries is expected to grow exponentially, driven by the rise in electric vehicles and renewable energy storage. Custom battery manufacturers are at the forefront of this shift, focusing on sustainable practices in custom power generation solutions. This blog explores how sustainability is integrated into the manufacturing of custom batteries.

Sustainable Materials and Sourcing

One of the primary ways custom battery manufacturers address sustainability is through the selection of materials. Traditional batteries often rely on materials like cobalt, which have significant environmental and ethical concerns due to their mining processes. In contrast, sustainable practices involve using materials that are abundant, non-toxic, and have a lower environmental impact. For example, lithium iron phosphate (LiFePO4) is a popular choice for its stability and lower environmental footprint compared to cobalt-based batteries. Additionally, manufacturers are increasingly sourcing materials from suppliers who adhere to sustainable mining practices, ensuring that the raw materials are ethically obtained.

Efficient Manufacturing Processes

The manufacturing process itself is another critical area where sustainability can be addressed. Custom battery manufacturers are implementing energy-efficient production techniques to reduce their carbon footprint. This includes using renewable energy sources such as solar or wind power in their manufacturing plants. Additionally, advances in automation and precision manufacturing technologies help reduce waste by ensuring that materials are used more efficiently. Manufacturers are also adopting lean manufacturing principles, which focus on minimizing waste and maximizing resource efficiency throughout the production process.

Battery Lifecycle Management

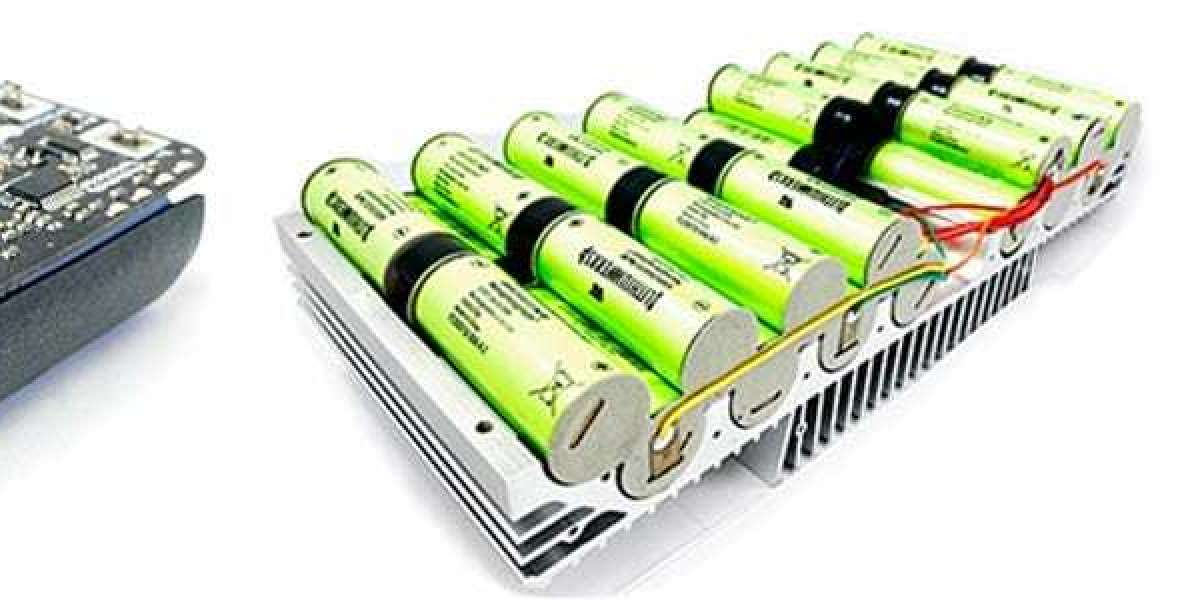

Sustainability in custom power generation extends beyond the manufacturing stage to the entire lifecycle of the battery. Custom battery manufacturers are developing batteries that have longer lifespans, thereby reducing the frequency of replacement and the associated environmental impact. This involves designing batteries that can withstand more charge and discharge cycles without significant degradation. Furthermore, manufacturers are focusing on modular designs that allow for easy repair and replacement of individual components, rather than discarding the entire battery.

Recycling and End-of-Life Management

Proper recycling and end-of-life management are essential components of sustainability in custom battery manufacturing. Manufacturers are creating take-back programs to ensure that batteries are returned for recycling rather than ending up in landfills. These programs facilitate the recovery of valuable materials such as lithium, nickel, and cobalt, which can be reused in new batteries. Additionally, advances in recycling technologies are making it possible to recover these materials more efficiently and with less environmental impact. Some companies are even designing batteries with recycling in mind, using materials and construction methods that make disassembly and material recovery easier.

Innovative Packaging and Transportation

Sustainable practices in custom battery manufacturing also extend to packaging and transportation. Manufacturers are opting for packaging materials that are recyclable or biodegradable to reduce waste. Additionally, they are designing packaging that minimizes the volume and weight of the batteries, which in turn reduces the carbon footprint associated with transportation. By optimizing the logistics and supply chain, manufacturers can further reduce the environmental impact of their products.

In conclusion

Sustainability in custom battery manufacturing is addressed through a multifaceted approach that includes sustainable materials and sourcing, efficient manufacturing processes, comprehensive lifecycle management, effective recycling and end-of-life strategies, innovative packaging and transportation, and adherence to regulatory standards. As the demand for custom power generation solutions continues to rise, custom battery manufacturers play a vital role in ensuring that these solutions are not only efficient and reliable but also environmentally responsible.