Introduction

Corrugated pipe cutting machines are specialized tools designed to cut corrugated pipes accurately and efficiently. These pipes, often made from materials like HDPE (High-Density Polyethylene) and corrugated pipe cutting machine india, are widely used in drainage systems, cable protection, and various industrial applications. In India, the demand for corrugated pipe cutting machines is growing due to infrastructure development and industrial expansion. This article explores the functionality, types, applications, and leading manufacturers of corrugated pipe cutting machines in India.

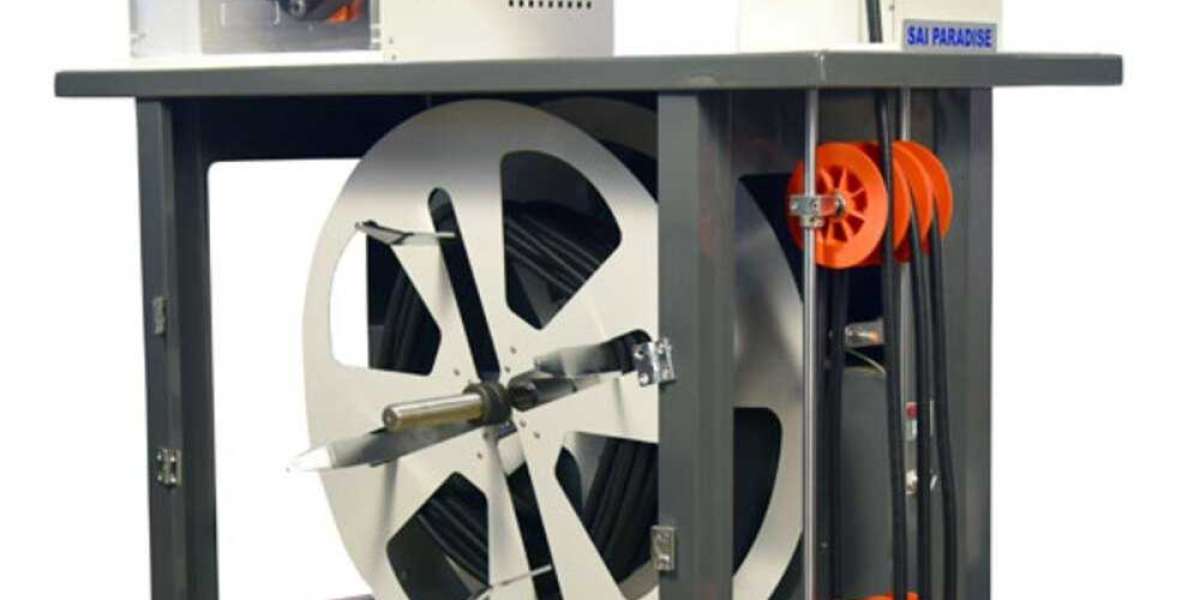

What is a Corrugated Pipe Cutting Machine?

A corrugated pipe cutting machine is designed to cut corrugated pipes to specified lengths and shapes with high precision. These machines can handle the unique challenges of cutting corrugated pipes, such as their flexible and ribbed structure. They are essential for ensuring the pipes meet the exact specifications required for various applications.

Key Features of Corrugated Pipe Cutting Machines

High Precision Cutting

Ensures clean and accurate cuts, minimizing waste and ensuring the pipes fit perfectly in their intended applications.

Automatic and Semi-Automatic Options

Available in both fully automatic and semi-automatic models to suit different production needs and budgets.

Adjustable Cutting Lengths

Allows for precise adjustments to meet specific length requirements, enhancing versatility.

User-Friendly Interface

Equipped with intuitive controls and displays for easy operation and monitoring.

Robust Construction

Built with durable materials to withstand the demands of continuous industrial use.

Safety Features

Includes safety mechanisms such as emergency stop buttons and protective guards to ensure operator safety.

Types of Corrugated Pipe Cutting Machines

Manual Corrugated Pipe Cutting Machines

Function: Operated manually, suitable for small-scale operations.

Applications: Ideal for workshops and small manufacturing units.

Semi-Automatic Corrugated Pipe Cutting Machines

Function: Combine manual loading with automated cutting processes.

Applications: Used in medium-scale production facilities requiring a balance between automation and manual control.

Fully Automatic Corrugated Pipe Cutting Machines

Function: Completely automate the loading, cutting, and unloading processes.

Applications: Employed in large-scale industrial operations where high efficiency and precision are required.

Rotary Corrugated Pipe Cutting Machines

Function: Use rotating blades or discs to cut pipes efficiently.

Applications: Suitable for high-speed cutting in continuous production lines.

Laser Corrugated Pipe Cutting Machines

Function: Utilize laser technology to achieve precise and clean cuts.

Applications: Ideal for applications requiring high precision and minimal deformation.

Applications of Corrugated Pipe Cutting Machines

Drainage Systems

Cutting pipes for underground drainage and stormwater management systems.

Cable Protection

Preparing corrugated pipes used for protecting electrical and communication cables.

Agriculture

Cutting pipes for irrigation and water management systems.

Construction

Producing pipes for various construction applications, including conduit and sewage systems.

Automotive Industry

Cutting pipes used in vehicle manufacturing for fluid transport and protective casing.

Industrial Applications

Preparing pipes for use in manufacturing equipment, machinery, and other industrial applications.

Benefits of Corrugated Pipe Cutting Machines

Enhanced Efficiency

Automating the cutting process reduces cycle times and increases production throughput.

Improved Precision

Ensures accurate cuts, reducing material waste and improving product quality.

Versatility

Capable of handling various pipe diameters and materials, making them suitable for diverse applications.

Reduced Labor Costs

Minimizes the need for manual labor, leading to cost savings and reduced risk of human error.

Increased Safety

Automation and safety features protect operators and reduce the risk of workplace injuries.

Scalability

Easily scalable to accommodate increased production demands or new product specifications.

Leading Manufacturers of Corrugated Pipe Cutting Machines in India

SMP Engineering

Known for its high-quality pipe cutting machines, SMP Engineering offers solutions that combine precision with durability.

Technocrats Plasma Systems

Specializes in advanced cutting technologies, including laser and plasma cutting machines, suitable for corrugated pipes.

Aditya Mechatroniks

Provides a range of CNC and automatic cutting machines designed for high efficiency and accuracy.

Conclusion

Corrugated pipe cutting machines are vital for enhancing the efficiency, precision, and safety of corrugated pipe cutting machine india. The growing infrastructure and industrial demands drive the adoption of advanced cutting technology. By understanding the types, applications, and benefits of corrugated pipe cutting machines, businesses can select the right equipment to optimize their operations and meet market demands.

Follow Us On More Links:-

Follow Us On Facebook:- https://www.facebook.com/people/SICA-India/100083115558219/

Follow Us On Instagram:- https://www.instagram.com/sica.india/

Follow Us On Linkedin:- https://www.linkedin.com/company/sica-india/

Address:- Next To Kanara Business Centre Compound, Laxmi Nagar, Opp. Andheri Link Road, Ghatkopar (East), Mumbai – 75.

Call US:- +91-22-62231691 / 96191-40918

Email Us:- info@sicaindia.com