The global aircraft health monitoring system market size was USD 4,202.4 million in 2019 and is projected to grow from USD 2,319.7 million in 2020 to USD 4,987.9 million in 2027 at a CAGR of 11.56% in the 2020-2027 period. The sudden rise in CAGR is attributable to this market’s demand and growth returning to pre-pandemic levels once the pandemic is over. Aircraft Health Monitoring System (AHMS), also known as Aircraft Condition Monitoring System (ACMS) or Aircraft Health and Usage Monitoring System (AHUMS), is a comprehensive and sophisticated technology used in the aviation industry to monitor the health, performance, and usage of aircraft systems in real-time.

Informational Source:

https://www.fortunebusinessinsights.com/aircraft-health-monitoring-system-market-105027

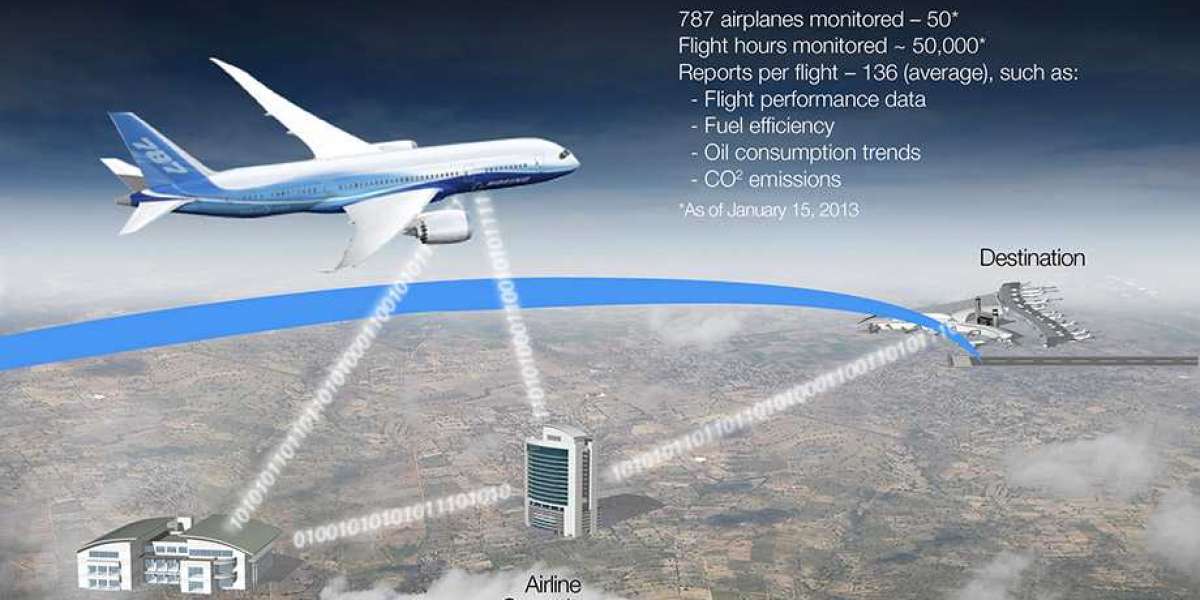

An Aircraft Health Monitoring System (AHMS) is a sophisticated technology employed in aviation to monitor the condition, performance, and operational parameters of an aircraft in real-time. This system involves the installation of various sensors throughout the aircraft, which continuously gather data on factors such as engine parameters, structural integrity, fuel levels, temperature, and more. The collected data is then transmitted to ground stations via communication channels, where it is processed and analyzed using advanced algorithms. AHMS provides critical insights to pilots, maintenance crews, and operators, enabling them to make informed decisions about the aircraft's health and maintenance needs. By detecting potential issues early, AHMS enhances safety, reduces downtime, lowers maintenance costs, and improves overall operational efficiency for airlines.

Major Companies Covered in Aircraft Health Monitoring System Market are:

- Airbus S.A.S. (The Netherlands)

- Boeing (US)

- United Technologies Corporation (US)

- Honeywell International, Inc. (US)

- General Electric Company (US)

- Rolls Royce (UK)

- SAFRAN (France)

- FLYHT (Canada)

- Curtiss-Wright (US)

- Tech Mahindra (India)

- Meggitt (UK)

- Lufthansa Technik (Germany)

- Other Players

Aircraft Health Monitoring Systems offer a proactive approach to maintenance by enabling predictive and condition-based maintenance strategies. The system's ability to identify trends, anomalies, and deviations from normal operating parameters allows for timely interventions, preventing potential failures and ensuring a higher level of aircraft reliability. The data-driven nature of AHMS empowers airlines to optimize fleet management, streamline maintenance schedules, and maximize resource utilization. Moreover, AHMS supports regulatory compliance by providing comprehensive maintenance records and documentation. As technology continues to evolve, Aircraft Health Monitoring Systems are becoming increasingly integral to aviation operations, contributing significantly to the safety, performance, and economic sustainability of modern aircraft fleets.

The primary goal of an AHMS is to enhance aircraft safety, reduce maintenance costs, and improve operational efficiency by providing timely and accurate information about the aircraft's condition. Here's an in-depth overview of AHMS:

1. Overview and Importance: Aircraft are complex machines with numerous interconnected systems that need to function optimally for safe and efficient flight. Monitoring these systems in real-time is crucial to prevent issues, reduce unplanned downtime, and ensure the safety of passengers and crew. AHMS offers a proactive approach to aircraft maintenance by providing continuous monitoring and analysis of various parameters.

2. Components of AHMS: An AHMS consists of several interconnected components that work together to gather, transmit, analyze, and present data. These components include:

Sensors: Various types of sensors are installed throughout the aircraft to collect data on parameters like temperature, pressure, vibration, fluid levels, engine parameters, structural stress, and more.

Data Acquisition Units (DAUs): DAUs gather data from the sensors and convert analog signals into digital data. These units are responsible for transmitting the collected data to the central data processing system.

Data Transmission: Data collected by DAUs is transmitted to ground stations via satellite communication, Wi-Fi, cellular networks, or other communication technologies. This allows maintenance personnel and operators to remotely access real-time information about the aircraft.

Data Processing and Analysis: On the ground, powerful computers and software systems process and analyze the collected data. Advanced algorithms identify trends, anomalies, and potential issues. Machine learning techniques might be employed to improve the system's ability to predict maintenance needs.

Cockpit Displays and Alerts: Pilots receive real-time information about the aircraft's health on cockpit displays. In the case of critical issues, warnings and alerts are generated to prompt necessary actions.

Maintenance Control Centers: Airlines and maintenance crews have access to a centralized control center where they can monitor the entire fleet's health, schedule maintenance, and respond to alerts.

3. Benefits of AHMS:

Improved Safety: By continuously monitoring the aircraft's health, potential problems can be identified and addressed before they escalate into safety concerns.

Reduced Downtime: Predictive maintenance based on AHMS data allows airlines to plan maintenance activities during scheduled downtimes, reducing unscheduled maintenance and minimizing operational disruptions.

Cost Savings: AHMS helps optimize maintenance schedules, reduces the need for invasive inspections, and minimizes the replacement of parts that are still functional, leading to significant cost savings.

Enhanced Efficiency: The system allows operators to optimize flight routes and operational parameters based on real-time data, improving fuel efficiency and overall operational performance.

Regulatory Compliance: AHMS can assist airlines in meeting regulatory requirements by providing accurate and comprehensive maintenance records.

4. Challenges:

Data Security: The transmission and storage of sensitive aircraft data raise concerns about data security and cyberattacks.

Integration Complexity: Installing AHMS components in existing aircraft can be complex, requiring careful integration with the aircraft's systems and avionics.

Data Interpretation: Analyzing the vast amount of data generated by AHMS requires sophisticated algorithms and skilled personnel.

5. Examples of AHMS Systems: Several aircraft manufacturers and service providers offer AHMS solutions, including Boeing's Airplane Health Management, Airbus's Airman, and various third-party systems provided by companies like Honeywell and GE Aviation.

In conclusion, Aircraft Health Monitoring Systems play a crucial role in modern aviation by providing real-time insights into aircraft health, thereby improving safety, efficiency, and cost-effectiveness. The continuous advancement of sensor technology, data analytics, and communication systems continues to enhance the capabilities of AHMS, making it an integral part of the aviation industry.